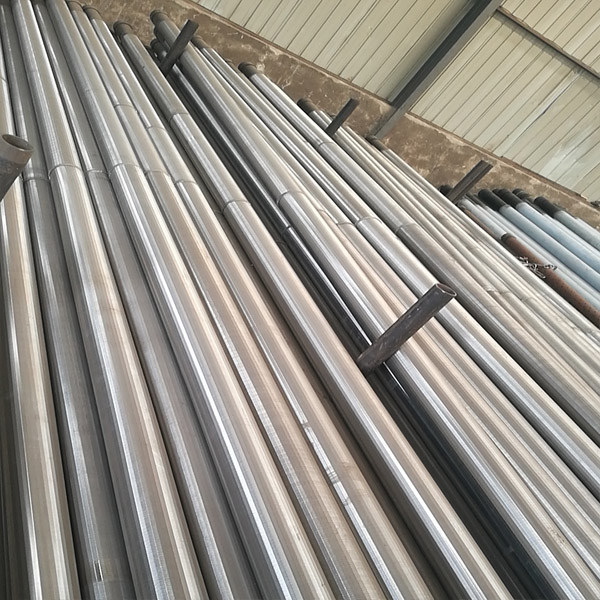

Stainless steel mesh wrapped wire filter pipe

Pic-(Stainless steel mesh wrapped wire filter pipe )

The wire wrapped sieve tube is widely used in the sand control industry of oil, gas, and water wells, with a particularly prominent position in the water well industry. It is a widely used type of water resource filtration sieve tube.

The wire wrapped sieve tube adopts advanced full welding production technology, and is welded on a set of supporting wires arranged in a circular pattern using specially designed trapezoidal wire windings. Full welding ensures strict continuity and integrity of the product, resulting in a larger gap size and maximum ability to withstand high pressure.

Each production process is carried out by professional personnel using advanced and sophisticated professional equipment. Product specifications and raw materials can be specially customized according to customer needs. All products are strictly produced and inspected in accordance with SY/5182-2008 standards to ensure product quality and protect the interests of our customers.

Product advantages

·The small gap opening on the surface and the large gap opening below make the gap self-cleaning, ensuring smooth fluid filtration and providing assurance for improving production efficiency and extending the service life of the filter.

·The wire winding is connected to all supporting bars through full process welding, which is sturdy, durable, and has a longer working life cycle.

·The minimum width of the opening gap reaches 0.1mm, which can meet the needs of the vast majority of sand control work. With the same filtration accuracy, the flow area is higher.

·We can customize different specifications and raw materials (mainly stainless steel and carbon steel) according to the actual needs of customers, in order to ensure reasonable investment and save production costs; Non stainless steel products can form a protective layer through galvanizing treatment, with a beautiful and clean appearance.

Product parameters

|

|

Base pipe

|

|||||

|

Model |

0.D |

Recommended Thickness

|

I.D |

Theoretica Weight |

Holes OD |

|

|

mm(in)

|

mm(in) | mm(in) |

kg/m(lb/ft)

|

mm(in)

|

||

| 1 |

RRS60

|

60.3(2-3/8)

|

4.83(0.190)

|

50.7(1.995)

|

6.85(4.60)

|

9(0.355)

|

| 2 |

RRS73

|

73.0 (2-7/8)

|

5.51(0.217)

|

62(2.441)

|

9.52(6.40)

|

9(0.355)

|

| 3 |

RRS89

|

88.9(3-1/2)

|

6.45(0.254)

|

76(2.992)

|

13.69(9.20)

|

10(0.4)

|

| 4 |

RRS102

|

101.6(4)

|

5.74(0.226)

|

90.1(3.548)

|

14.13(9.50)

|

10(0.4)

|

| 5 |

RRS114

|

114.3(4-1/2)

|

6.35(0.250)

|

101.6(4)

|

17.26(11.60)

|

10(0.4)

|

| 6 |

RRS127

|

127(5)

|

7.52(0.296)

|

112(4.408)

|

22.32(15.00)

|

10(0.4)

|

| 7 |

RRS140

|

139.7(5-1/2)

|

7.72(0.304)

|

124.3(4.892)

|

25.30(17.00)

|

10(0.4)

|

| 8 |

RRS168

|

168.3(6-5/8)

|

8.94(0.352)

|

150.4(5.921)

|

35.72(24.00)

|

10(0.4)

|

| 9 |

RRS178

|

177.8(7)

|

9.19(0.362)

|

159.4(6.276)

|

38.69(26.00)

|

10(0.4)

|

| 10 | other | |

||||